Water heating has been traditionally done by energy intensive & costly processes of electric geysers, burning diesel or coal or highly inefficient process of burning firewood. We present a new more efficient process of using ambient heat (i.e. heat in the air). This heat pump works on the traditional Carnot cycle. The application of this heater is across domestic and commercial segments ranging from homes & villas to hotels & swimming pools.

- Trueskill Energen presents the fourth generation water heater which has operating cost of 1/4 th of electric geysers and 1/3 rd of gas or diesel. Even the operating cost of electric boosted solar is greater than that of Air Source Water Heater.

- With a payback of less than a year, this is a revolutionary choice in water heating

- Very few moving parts so low or no maintenance

- This is a solution which ensures 24 x 7 x 365 days availability of hot water irrespective of climatic conditions. Air Source Water Heater can provide hot water even in winter.

- High efficiency of 400%+ ensures high energy saving

- Cold air at 20°C is a by-product which can be ducted to reduce Air Conditioning bills

- Occupying a fraction of space compared to solar heater and placement choice of virtually anywhere saving valuable area

- A life-span of 10+ years

- Safe to operate since there is no heating element or burning fuel

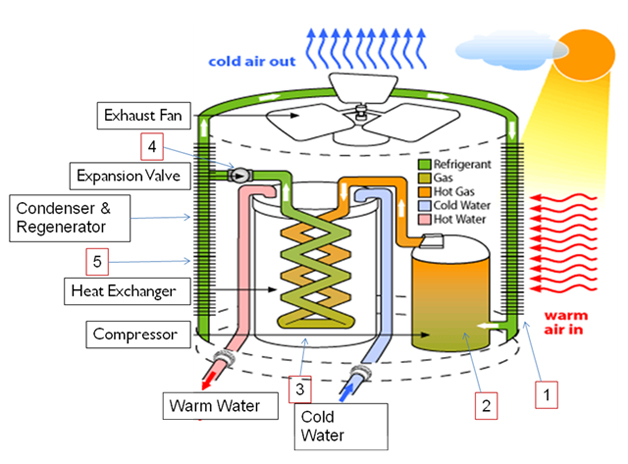

Working of the Air Source Water Heater:

Air Source Water Heater (ASWH) is a heat pump that uses the same principle as refrigerators to generate hot water. Unlike conventional electricity and fossil-fuel-fired water heaters, ASWH takes heat from the surrounding air and transfers it to the water in the tank.

Heat pumps mainly consist of a compressor, fan, evaporator, and the heat exchanger. Electricity is required only for the compressor and fan. The compressor is required to compress the refrigerant and vaporize it, and the fan to continuously blow air across the evaporator coils when the unit is operating.

- Ambient air is passed over evaporator coils containing a low pressure low temperature refrigerant which boils and vapourizes

- This vapour is further compressed which further increases its temperature to 120°C

- This high pressure high temperature refrigerant is passed through a heat exchanger where its latent heat is passed on to the water and the refrigerant temperature decreases

- The high pressure low temperature refrigerant then passes through an expansion valve where it becomes low pressure and low temperature liquid

- This passes through the condenser and regenerator and goes to the evaporator (point 1) for the cycle to restart